Gorilla Buck Window & Door Bucks for ICF Construction in GA

After working for over 20 years in the Insulating Concrete Form construction industry, Gorilla Buck decided there must be an easier way to deal with the ICF buck components and their inherent issues which ICF builders in the business know so well: the water and air leaks, the warping, the inconvenience of strapping the outside and inside of typical wood buck frames. Not to mention the custom cutting of lumber on site to match ICF wall thickness.

After working for over 20 years in the Insulating Concrete Form construction industry, Gorilla Buck decided there must be an easier way to deal with the ICF buck components and their inherent issues which ICF builders in the business know so well: the water and air leaks, the warping, the inconvenience of strapping the outside and inside of typical wood buck frames. Not to mention the custom cutting of lumber on site to match ICF wall thickness.

For these reasons, Gorilla Buck decided to develop their own buck product line to provide contractors, GCs, builders, and homeowners with a cost effective, easy to install, competitively priced system designed to save you from the headaches of traditional bucks. Green Harbor Building Systems GA believe Gorilla Buck have achieved this and have come up with the perfect solution!

Whether you’re an architect or designer wanting to match an existing ICF wall spec on your sill, door, or walkout buck; a building profession or contractor looking to reduce your labor and material costs on a project, or a DIY homeowner looking for a high quality, easy to install green building product line which provides good value for your investment - the Gorilla Buck, ICF Window & Door Buck products are the perfect choice.

Gorilla Buck's philosophy, “…why build a great wall and then install substandard window and door frames?”

Contact us for more information, advice or a quote on Gorila Buck Window & Door Bucks for ICF construction in GA.

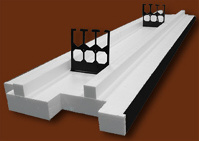

Molded Gorilla Buck

The Molded Gorilla Buck is the new standard for window and door openings for construction in the ICF industry. The exceptional design allows water to drain to the exterior of the building and allows for the flashing of windows and doors to go all the way back to concrete - the only buck product in the ICF industry to do this.

The Molded Gorilla Buck is the new standard for window and door openings for construction in the ICF industry. The exceptional design allows water to drain to the exterior of the building and allows for the flashing of windows and doors to go all the way back to concrete - the only buck product in the ICF industry to do this.

At the heart of the molded Gorilla Buck is special 100% recycled polystyrene plastic which bonds to the EPS foam, making for a much stronger and more rigid buck plank. The foam is molded around the continuous embedded plastic ladder with exposed edge plastic for the solid mounting of the windows and other trim elements. Bonding the ladder and buck to concrete are 3 rebar holder-anchors that fold into position.

Fireproof/Blastproof Molded Gorilla Buck

This buck provides a 2” wide opening in the face of the buck that is covered with a 1x4 screwed onto the face of the buck for stripping off after the concrete pour. The 2” strip of concrete around the complete buck frame opening that flushes out with the buck face provides a surface to mount doors and windows to and provides a code approved method for protecting against both fire and blasts.

This buck provides a 2” wide opening in the face of the buck that is covered with a 1x4 screwed onto the face of the buck for stripping off after the concrete pour. The 2” strip of concrete around the complete buck frame opening that flushes out with the buck face provides a surface to mount doors and windows to and provides a code approved method for protecting against both fire and blasts.

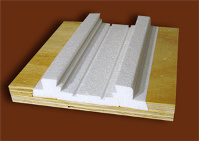

Standard Plywood Gorilla Buck

This product is the industry standard for Gorilla Buck. The 3/4” plywood buck, like all of their buck products, adds insulation to window and door frames to match the superior energy efficiency of the ICF wall. This was the first product that Gorilla Buck introduced - two pieces of premium plywood and EPS foam with multiple running beads of their adhesive applied then compressed and held in a hydraulic buck machine. It is then stapled together over a dozen times to ensure maximum strength and dimensional integrity. No twisting, no warping, no separation, with superb insulating qualities, made to your specifications and available locally.

This product is the industry standard for Gorilla Buck. The 3/4” plywood buck, like all of their buck products, adds insulation to window and door frames to match the superior energy efficiency of the ICF wall. This was the first product that Gorilla Buck introduced - two pieces of premium plywood and EPS foam with multiple running beads of their adhesive applied then compressed and held in a hydraulic buck machine. It is then stapled together over a dozen times to ensure maximum strength and dimensional integrity. No twisting, no warping, no separation, with superb insulating qualities, made to your specifications and available locally.

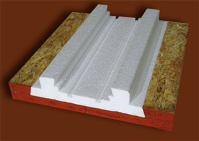

3/4" Treated Plywood Gorilla Bucks

Utilizing superior EPS in tandem with a treated plywood, this buck is generally recommended for areas within 6” of grade, such as walk-outs or door & window sill applications for the weather-facing sides of building. Additionally, this product can be used anywhere resistance to moisture or humidity is desired. In certain climates and conditions, this product is perfect when treated wood is recommended or required by local building codes to protect against decay, fungi, termites, carpenter ants or other wood destroying insects.

Utilizing superior EPS in tandem with a treated plywood, this buck is generally recommended for areas within 6” of grade, such as walk-outs or door & window sill applications for the weather-facing sides of building. Additionally, this product can be used anywhere resistance to moisture or humidity is desired. In certain climates and conditions, this product is perfect when treated wood is recommended or required by local building codes to protect against decay, fungi, termites, carpenter ants or other wood destroying insects.

Fireproof Plywood Gorilla Buck

The Fireproof Plywood Gorilla Buck is the ideal buck combination for those situations where code or architectural specifications call for fireproof qualities. Each of the Fireproof Plywood Gorilla Bucks as required by building codes, bears the Underwriters Laboratory classification mark identifying it as being produced under its classification and follow up service. This product can be painted or stained much like untreated wood.

The Fireproof Plywood Gorilla Buck is the ideal buck combination for those situations where code or architectural specifications call for fireproof qualities. Each of the Fireproof Plywood Gorilla Bucks as required by building codes, bears the Underwriters Laboratory classification mark identifying it as being produced under its classification and follow up service. This product can be painted or stained much like untreated wood.

3/4" OSB Gorilla Buck

This product is a contractor's preferred choice. Gorilla Bucks premium EPS combined with OSB strength, which comes mainly from the uninterrupted wood fiber interweaving of long strands or wafers, and degree of orientation of those strands in surface layers. This engineering process makes OSB the most widely accepted and preferred structural board among architects, specifiers and contractors. OSB resists deflection, delamination and warping because the wood and the adhesives work together to create a strong, dimensionally stable panel.

This product is a contractor's preferred choice. Gorilla Bucks premium EPS combined with OSB strength, which comes mainly from the uninterrupted wood fiber interweaving of long strands or wafers, and degree of orientation of those strands in surface layers. This engineering process makes OSB the most widely accepted and preferred structural board among architects, specifiers and contractors. OSB resists deflection, delamination and warping because the wood and the adhesives work together to create a strong, dimensionally stable panel.

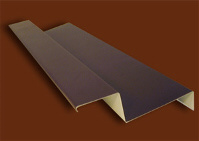

Gorilla Buck Flashing

Once again Gorilla Buck has gone the extra mile to eliminate any possibility of moisture penetration into sills or jams with their exclusive flashing. When coupled during the buck installation, the ICF form and buck create an impermeable barrier which prevents any incidental moisture from entering the sill or frame.

Once again Gorilla Buck has gone the extra mile to eliminate any possibility of moisture penetration into sills or jams with their exclusive flashing. When coupled during the buck installation, the ICF form and buck create an impermeable barrier which prevents any incidental moisture from entering the sill or frame.

Gorilla Buck Rebar Brackets

Another Gorilla Buck original! A quick horizontal cut with your circular saw allows the patented Gorilla Buck rebar brackets to be inserted through the span in the buck of your choice. A selection of holes allows you to easily align and steady most standard rebar sizes during your pour. This enables structural uniformity to be maintained, while our galvanized non-corrosive finish assures you of maintaining long term structural integrity.

Another Gorilla Buck original! A quick horizontal cut with your circular saw allows the patented Gorilla Buck rebar brackets to be inserted through the span in the buck of your choice. A selection of holes allows you to easily align and steady most standard rebar sizes during your pour. This enables structural uniformity to be maintained, while our galvanized non-corrosive finish assures you of maintaining long term structural integrity.

Get a free quotation for Gorilla Buck Window & Door Bucks for Insulated Concrete Form construction in Georgia here.

GET A FREE QUOTE FOR GORILLA BUCK GREEN BUILDING PRODUCTS FOR GA